Equipments

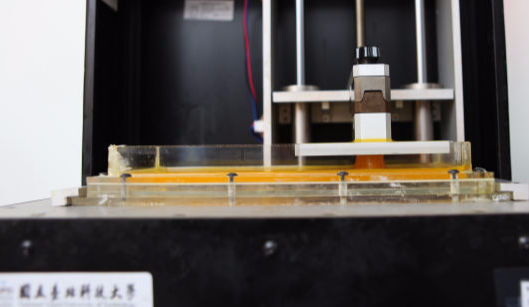

Circular Paving Solvent-based Slurry Stereolithography System

Solvent-based Slurry Stereolithography (3S) is an additive manufacturing process that follows the principle of laying the slurry ceramic suspension layer-by-layer. A semi-solid state of slurry layer is formed after the solvent is evaporated. Then a dynamic mask is projected by a digital light projector (DLP) to cures the reticle area.

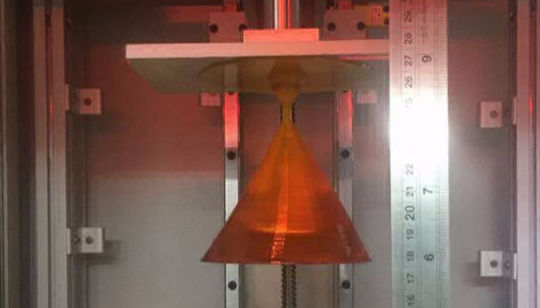

VP type high precision bottom-up system

Bottom exposure design, low pulling force, high precision and speed. Layer thickness adjustable between 0.01-0.2mm, Full-HD resolution and 30μm pixel size.

VP type large scale system

Large scale VP type 3D printers based on both Bottom-up and Top-down design.

Both have the ability to minimum resin requirement, high speed printing. Layer thickness adjusted between 0.05-0.3mm, Double Full-HD projectors to bring 1920X2160 resolution and 50-~200μm pixel size can be adjusted.

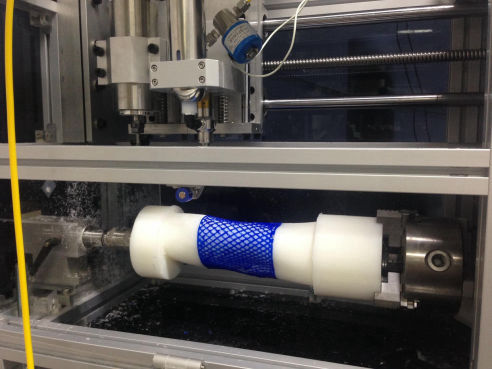

ME type Hybrid manufacturing system

The hybrid system is equipped by a CNC subtractive and Material Extrusion additive processes. The support model is first machined by CNC milling and followed by Material Extrusion, complex skeleton objects can be fabricated within this machine.

PBF type midsole manufacturing system

Dual-scanning near-infrared laser sintering system for TPU powder is used to fabricate multiple pair of midsoles together to speed up the printing and keep the light weight possible.

BJ type system

Advisor of Microjet to build up the T10 machine.

ME type porcelain system

The XYZ Material extrusion type porcelain system has a build volume of 300 x300x380 mm.

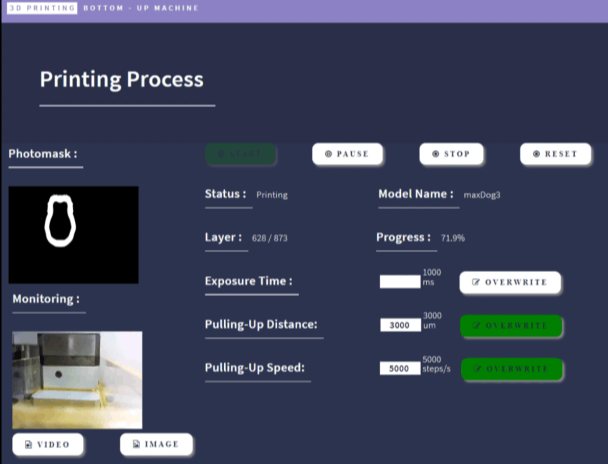

Internet of Additive Manufacturing System (AM+ IoT)

The Internet of Additive manufacturing system (IoAM) is used to control a rack 3D printers from different devices and workstations through internet connection. It is also equipped by an adaptive controller for the printing parameters to speed up the fabrication process.